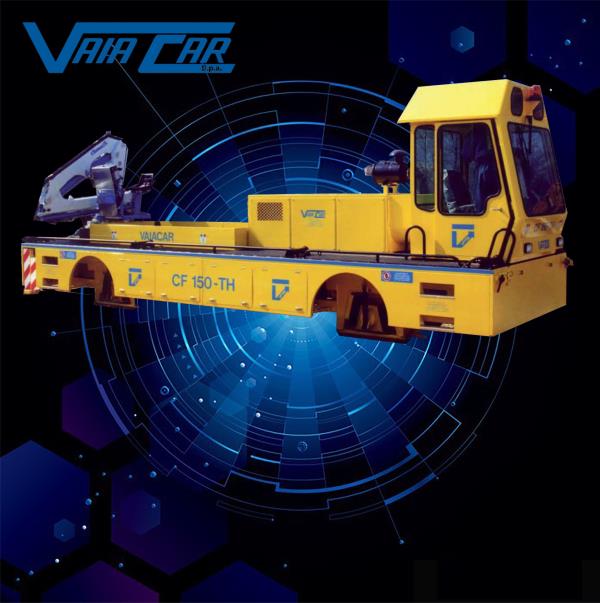

The most advanced system (VAIA CAR Patented) to weld, destress and quench simultaneously any existing rail profile included Vignole and ables to destress up to 1.0 Km of rail lenght. This welding head can be used both in mobile mode and fixed plant.

Do you want to know more?

WRITE US NOW

Create for mobiles and fix applications, the new VAIA CAR KUBE Flash Butt Welding Head is the most advanced system to weld, destress and quench simultaneously any existing rail profile included Vignole and allowsdestressing operations up to 1.0 Km of rail lenght.

Ensures the track stability and eliminates the risk of trains derailment.

ADVANTAGES

- Integrated post welding quenching system.

- Indipendent integrated shearing blade patented system.

- Destressing integrated patented system.

- Reduced welding soft section area.

- Excellent rail alignment and rail geometry.

- No more rail heating systems are required.

- Elimination of aluminothermic welding junctions (cause of frequent crackings).

- Double resistence of bending tests.

- High quality of welding process and post welding results as for EN 14587.

- High productivity and efficiency standards.

- Set-up of all machine functions from remote.

- Low maintenance costs.

- Easy to operate.

CAPABILITY

- Forging capacity up to 2000 kN for destressing operation.

- Welding capability up to 12000 mm2.

- Weight: 4200 kg.

- Dimensions: 2300 mm (lenght for excellent rail alignment) x 1150 mm x 1050 mm.