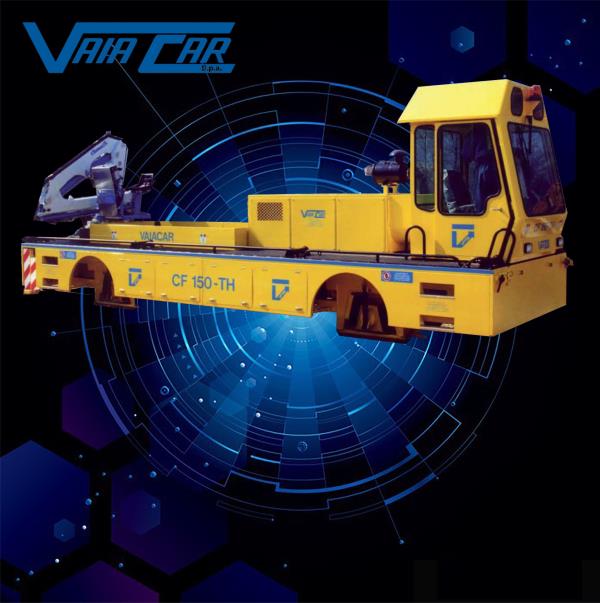

Tamping systems

Engine

| Type |

HATZ |

| Cycle |

DIESEL |

| Injection |

DIRECT |

| Engine size |

2574cc |

| N° cylinders |

3 IN LINE |

| Cooling |

BY AIR |

| Power |

35.9 KW (49 HP) a 3000 g/1' |

| Specific consumption |

245 g/KWh a 2500 g/1' |

| Engine torque |

170 Nm a 2000 g/1' |

Do you want to know more?

WRITE US NOW

Translation

hydraulic translation with fixed displacement engine that transmits the motion to the rail wheels by means of a mechanical chain drive.

Max. speed

20 Km/h.

Structure

this consists of an electrically-welded framework made of composite beams, tubular section beams for the extending of the horizontal columns and rail-extractors, and of two vertical side-columns. The hydraulic lifting cylinders of the side-columns are protected by the telescopic tubular system. The structure houses: the diesel engine, hydraulic pumps, hydraulic distributors with control levers, hydraulic oil tank and fuel tank, battery, drive engine with complete mechanical transmission, four rail-wheels, driving seat with appropriate safety devices. The telescopic lifting columns are independent and can be extended vertically by 1800+660 mm. The horizontal supporting columns are independent and can be laterally extended by 1000mm in both directions. Last but not least, the rail-extractor horizontal support columns are both independent and can be extended by 530 mm. The rail-extractors are also equipped with a mechanical device for adjusting the height required for gripping the various types of rails. Moreover the new lifting machine is able to perform longitudinal movements (of up to 160 mm) for the purpose of centring the laying position of the track panel or the points.

Tamping system

Next to the lifting system, there is a tamping system consisting of a pair of electro-hydraulically controlled mobile tamping heads powered by an additional pump which enables them to tamp any type of track. The tamping heads are able to perform longitudinal movements of 350 mm in order to position themselves on the sleeper to be tamped, and lateral movements of 620 mm in order to be able to adapt to all types of rail gauge. Moreover, the hook of the front rail can perform a longitudinal movement of 400 mm which, combined with the longitudinal movement of the tamping heads, enables easy positioning and hooking of the rail at all times.

Gauge

the machine can be set up with any kind of gauge.

Lifting capacity

30,000 KG (30 Ton.)

Total mass

7,100 KG (7.1 Ton.)

Certifications

the VAIACAR SI-300 type system, constructed following the current Community Directives, has been CE certified and is in compliance with all the applicable standards.